New Paper on Plasticity and fracture of cast and SLM AlSi10Mg

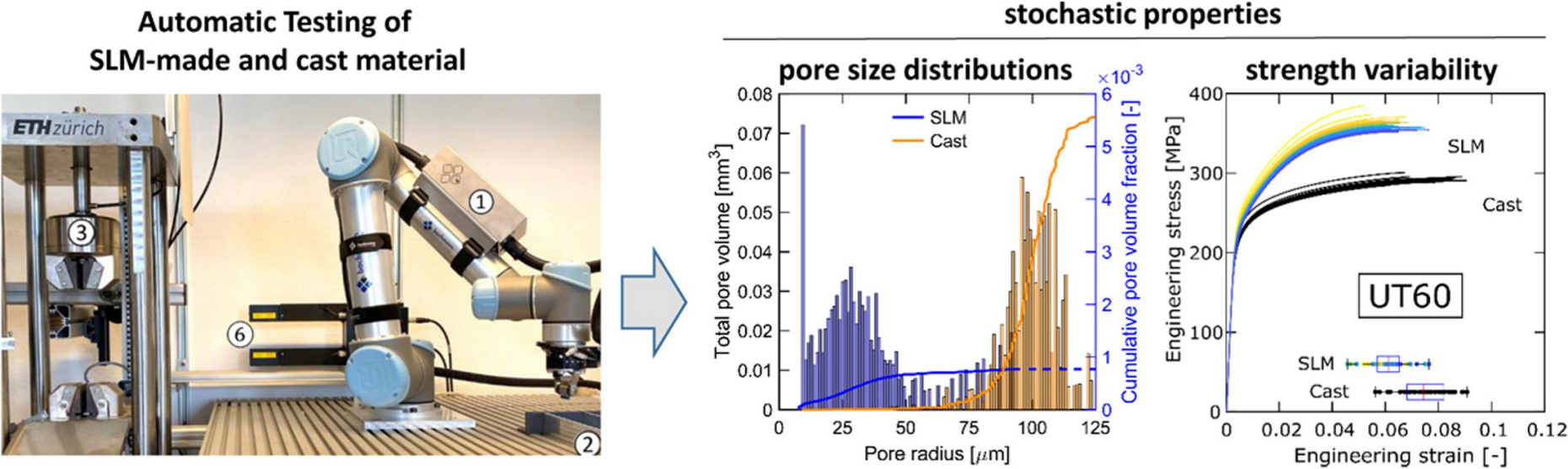

Our paper on "Plasticity and fracture of cast and SLM AlSi10Mg: High-throughput testing and modeling" was published in Additive Manufacturing

Abstract

Both additively-manufactured and cast metals are known to exhibit stochastic mechanical properties at the macroscopic level. Using a robot-assisted mechanical testing system, more than 360 experiments are performed on flat specimens extracted from AlSi10Mg components that are either cast or made through laser powder bed fusion (LPBF), commonly known as selective laser melting (SLM). Aside from basic EBSD analysis of the respective microstructures, micro-computed tomography is performed revealing a significantly higher porosity and pore size for the cast material. The results from uniaxial tension experiments reveal a 10% higher yield strength (on average) and an about 20% higher ultimate tensile strength for the SLM made AlSi10Mg. The tracking of the specimen origin within the SLM component shows a clear location dependence of the observed hardening response on the build height. The shear and tension fracture experiments revealed a strong stress-state dependence and significantly higher fracture strains for the cast material as compared to its SLM-made counterpart. To facilitate the computer aided engineering of structures with additively-manufactured AlSiMg alloys, a build height dependent hardening model is proposed along with a probabilistic plasticity and fracture modeling framework.