Impact Engineering

In-page quick links:

Split-Hopkinson Pressure Bar setups are used to investigate material behavior at high strain rates, as they occur for example in forming applications or accidental loadings. On our 20m long test bench, a variety of Hopkinson bar setups can be mounted ranging from compression and direct impact to tension. In addition experiments can also be performed at elevated and high temperatures.

The image below shows the test bench with a high-speed optical camera (top) and high-speed infrared camera (left) mounted above the Load-inversion device. In addition videos from High-Speed Photography and Digital Image Correlation of a notched sample are shown. The test duration is approximately 0.6ms (milliseconds).

Induction Heating

Impact events require an understanding of the material response at elevated temperatures. These tests can be performed using induction heating, with which temperatures up to the melting point of the respective (conductive) material can be reached within seconds (e.g. steel >1000°C).

Temperature Measurement

Thermocouples, pyrometers or slow infrared (IR) cameras can be used to accurately measure temperatures during experiments with little temperature change. To investigate the amount of plastic work converted into heat during intermediate and high strain rate experiments, an IR high speed camera is used. The video below shows the temperature field, the strain field and the corresponding force-displacement curve for a notched tension experiment at an intermediate strain rate ~1/s.

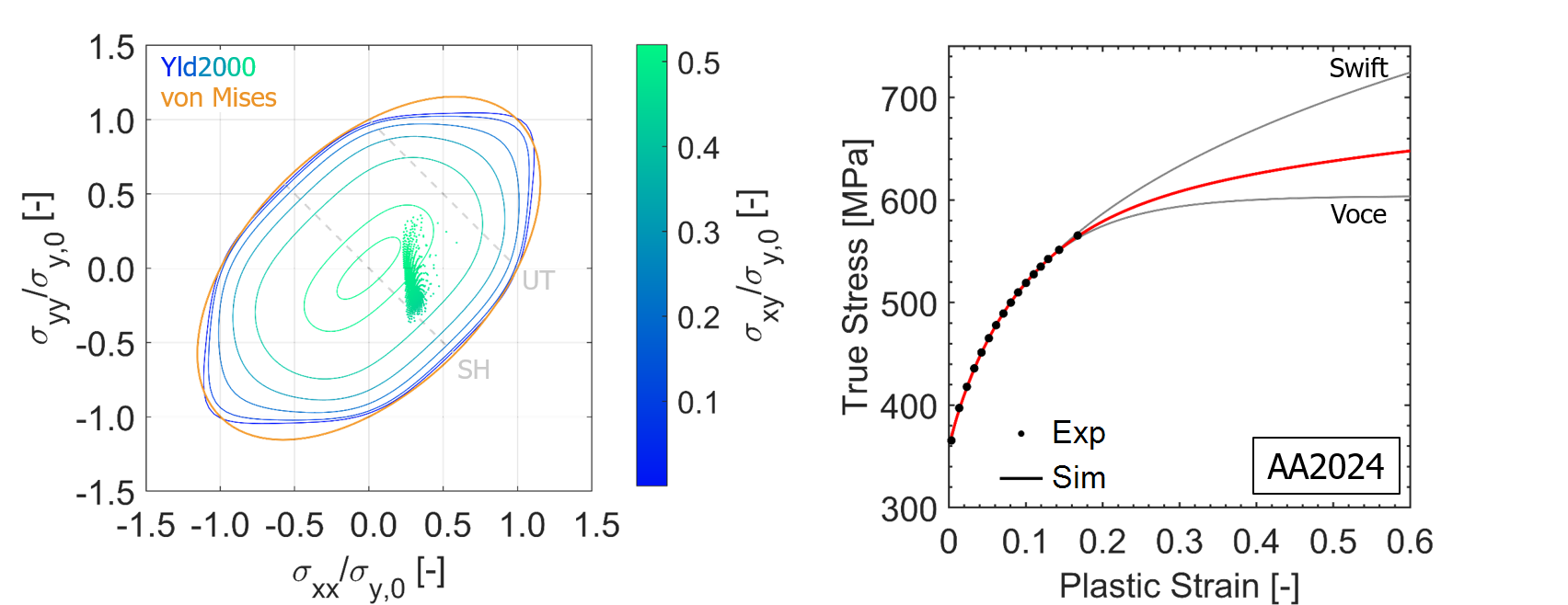

Data from experiments is used to model the plastic response of various materials. Once the model parameters have been identified, numerical simulations are performed to further investigate the material behavior.

Prediciting the onset of fracture in ductile materials is at the heart of our research and finds applications in many real world settings. Besides the effect of strain rate, the influence of temperature on the fracture response is of interest to us.

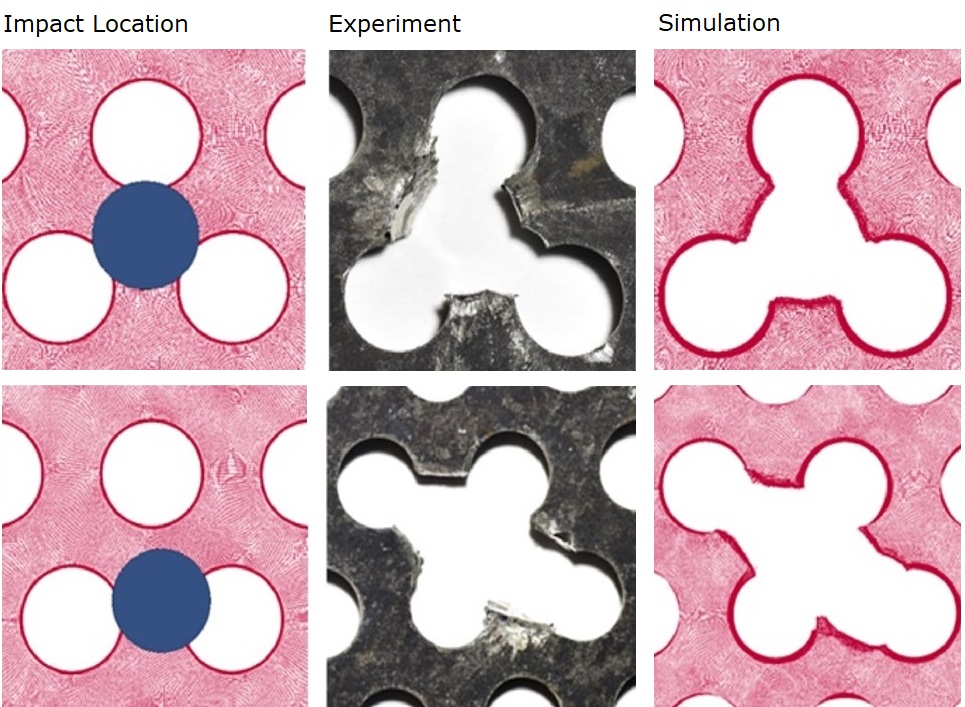

The application of a strain rate and temperature dependent plasticity and fracture model is shown for an accidental loading of a perforated plate. On the left, the impact location is indicated in blue, while the post-impact results are shown in the middle (experiment) and on the right (simulation).

The advent of electric vehicles raises the question of the safety of their largest and most sensitive component, the battery pack and its individual cells. Upon crash loading, the cells undergo large deformations possibly leading to short circuit and thermal runaway, potentially creating fires. The accurate mechanical modeling of lithium-ion cells is paramount to the safety of electric vehicles. This line of research is the latest addition to the topics investigated in the Chair of Artificial Intelligence in Mechanics and Manufacturing and leverages the knowledge acquired in the other research areas of the lab.

Lithium-ion cells are a very complex multiphysics system as they are composed of a periodic assembly of cathode, separator and anode, representing a total of five solid materials all of them immersed in an electrolyte (liquid or gel). Each material responds to many external stimuli such as electrical current, ion concentration, temperature and stresses. The accurate modeling of the materials and their interactions is necessary to predict the mechanical response of the cell for different stress states, strain rate as well as electrochemical parameters e.g. the state of charge and the state of health.