New Paper on Using miniature experiments

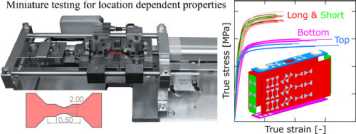

Our new paper on "Using miniature experiments to reveal strenght gradients in battery casings" was published in International Journal of Mechanical Sciences

Abstract

Complex metallic structures are often manufactured through multi-step forming or casting processes that induce severe mechanical property variations within the final part. Instead of using the virgin material properties to predict the final part performance, the local material properties after manufacturing need to be known. A novel comprehensive testing methodology is presented allowing the resolution of spatial gradients in the plasticity and fracture properties in metallic structures. It involves using a recently-developed miniature linear-motion system that probes the material within 2 mm wide gage sections (uniaxial, notched and central hole tension, in-plane shear). Additionally, a novel mini-bulge testing system is presented along with a mini-punch system to provide further insight into the local material response for biaxial loading conditions. A full testing campaign comprising 60 miniature samples is performed on all sides of a prismatic aluminum casing for Li-ion battery cells. The results demonstrate significant property variations with more than 30 % higher yield stresses for the side walls as compared to the bottom section. The miniature specimens allow identifying a location-dependent anisotropy, which would otherwise be missed by standard-sized samples. Furthermore, it is shown that the anisotropic Yld2000 plasticity model and the stress-state dependent Hosford-Coulomb external page fracture initiation model can be fully identified using results from experiments on miniature specimens only.