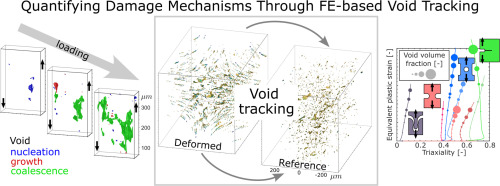

New Paper on Quantifying Damage Mechanisms Through FE-based Void Tracking

Our new paper on "Quantifying DamageOur new Paper on "Quantifying Damage Mechanisms Through FE-based Void Tracking: Application to Shear and Tension In-situ Laminography Experiments on AA2198-T851" was published in Acta Materialia

Abstractexternal page

This study presents a hybrid experimental-numerical postprocessing technique for analyzing damage evolution during in-situ tomography experiments. Using the displacement fields obtained from finite-element (FE) simulations as initial guesses, voids are tracked throughout loading by mapping their centroids to the initial configuration with a novel void tracking algorithm. This algorithm facilitates differentiation between void nucleation, growth and/or coalescence of existing voids. In-situ laminography experiments are performed on flat shear, central-hole tension, notched tension and compact tension specimens extracted from recrystallized aluminum alloy 2198-T851. The specimens are monotonically loaded all the way to fracture to gain insight into ductile failure mechanisms for predominantly biaxial stress states. Detailed 3D gray scale images are acquired at multiple stages of each experiment, allowing distinguishing between polycrystalline matrix, inter-metallic particles and voids at sub-micrometer resolution. The postprocessing of all experiments leads to a wealth of experimental data on void sizes, shapes, counts, volume fractions, and mechanisms of origin. Average stress states and macroscopic strain estimates are derived using continuum scale FE simulations with an anisotropic non-porous plasticity model and related to the void evolution. The tomographic observations show two primary damage mechanisms at early plastic straining stages: (1) intermetallic particle cracking and debonding, and (2) micro-crack emergence mainly at grain boundaries. At high plastic straining stages, grain boundary unzipping leads to fracture via micro-crack growth and coalescence, more prevalent under generalized shear than tension. It is found that particle-related void growth is slow and enhances the material's macroscopic ductility by delaying the growth of large voids.